Exploring Opportunities: Why your business is a ‘Factory’?

In the last 20 years, the drive to become more efficient within a factory environment has been intensified by manufacturing competition on a global scale. This is largely due to the major inroads into productivity improvement that the Toyota car company introduced. These are now widely known as Lean Manufacturing. Why your business is a ‘Factory’?

Although not all manufacturing businesses have had the vision to apply Lean Manufacturing processes, the big opportunity lies in non-manufacturing businesses who often don’t see the comparison between their operation and that of a highly productive automotive factory. Therefore, they are failing to learn and capitalise on the major benefits that can be achieved.

So where are the opportunity areas?

People, information & goods processing is just like product processing. In the manufacturing industry, those who have applied Lean Manufacturing have identified the 7 wastes within their business and systematically eliminated these wastes by re-mapping their processes. In non-manufacturing applications, the first step is that management needs to understand, that whatever the business, it consists of a number of processes which, until optimised, are highly likely to contain many instances of the 7 wastes.

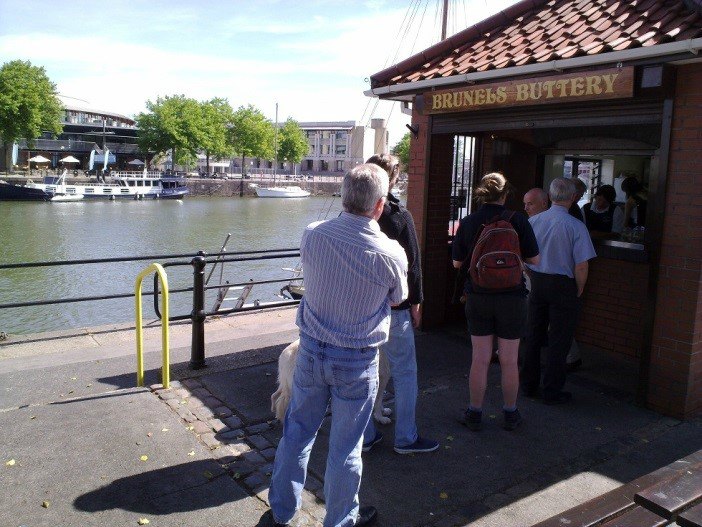

In my day to day observations, there are many, many businesses and services which are clearly overrun by the 7 wastes. Some suggested opportunity areas are: Utility companies, train operators, bus operators, petrol station refilling, hotels, universities, hospitals, airports, call centres, shops, cafes & restaurants to name a few.

So how does this Waste manifest itself?

Put another way, why is this a problem to the business owner? Being Lean is about being efficient. That, in turn, means higher performance in 3 key areas; Quality, Lead time and Cost.

- Quality – The number one reason why the customer will not come back

- Lead Time – In today’s environment, people want the product today, not tomorrow or in 6 weeks’ time. It is hard to believe that when you go to order something from a large department store they tell you it will be 6-8 weeks delivery. It is unbelievable that this can still exist in today’s environment. Maybe, these businesses will not go bust tomorrow but over the next 5-10 years, this type of lead time will cease to exist.

- Cost – You can buy a cable to connect your iPhone to your car audio system from somewhere on the high Street like PC World or Currys for around £9.99, or, you can buy it online through Amazon who will ship apart, with the same function, all the way from China, within a very short lead time, for around £3. Need I say any more on how important it is to control costs within your processes?

Know your runners, repeaters and specials

There is a lot of information out there on the 7 wastes. It is worthwhile reading and understanding this information to become Lean and make your business a sustainable one. One of the things I have learned about Lean in my time and which has stood me in good stead for understanding and supporting customers has been the concept of Runners, Repeaters and Specials. Every business should know what constitutes its runners, repeaters and specials and be set up in a way that deals with each of these 3 categories of products or services appropriately.

Let’s consider some examples of opportunities:

A large queue outside a popular restaurant. Good point, it must be something worth having, therefore, I will also queue. Longer term, this is a missed opportunity for a much higher turnover for the restaurant. If they could process these people faster then they would be turning over cash at a higher rate and also reducing the risk of people walking away because the queue is too long.

A large queue outside a popular restaurant. Good point, it must be something worth having, therefore, I will also queue. Longer term, this is a missed opportunity for a much higher turnover for the restaurant. If they could process these people faster then they would be turning over cash at a higher rate and also reducing the risk of people walking away because the queue is too long.

On a smaller scale. I often walk past this (very good) cafe and see a large queue of people waiting for very standard products. On a busy Sunday morning, you can wait 10-15 minutes to pick up a bacon sandwich. For this coffee, the classic bacon sandwich represents a “runner;” it is reasonable to assume that they will sell a high number of these on a typical Sunday morning, therefore they should have a specific process for churning out bacon sandwiches just as fast as McDonald’s do with Big Macs. Reality is, each customer order for a bacon sandwich is treated as a special and therefore people have to wait. Bottom line; some people, not all, will turn away because of the queue.

A very well-known and classic example of waste. Whilst you are queuing for 30-45 minutes to check-in your baggage you could have been spending money in the cafes, duty-free shops and restaurants on the other side. On a recent skiing trip, I flew back into Bristol Airport. It took 65 minutes to process me from the aeroplane through passport control through baggage collection and eventually to the door of the airport – a distance which you could walk in a straight line in around 3 minutes. So where was the waste?

A very well-known and classic example of waste. Whilst you are queuing for 30-45 minutes to check-in your baggage you could have been spending money in the cafes, duty-free shops and restaurants on the other side. On a recent skiing trip, I flew back into Bristol Airport. It took 65 minutes to process me from the aeroplane through passport control through baggage collection and eventually to the door of the airport – a distance which you could walk in a straight line in around 3 minutes. So where was the waste?

How many people each year in the UK are wound up by ordering and paying for something and then being told that it will be delivered any time between 8 AM and 6 PM and if you are not in you may have to pay for a re-delivery? In the past, that was accepted but in my opinion that will become the past as more proactive companies look to deploy practices such as the one in the photograph.

How many people each year in the UK are wound up by ordering and paying for something and then being told that it will be delivered any time between 8 AM and 6 PM and if you are not in you may have to pay for a re-delivery? In the past, that was accepted but in my opinion that will become the past as more proactive companies look to deploy practices such as the one in the photograph.

Share: