How Root Cause Analysis Can Help You Predict the Future

I am often asked “Is the right strategy to start applying root cause analysis at the beginning of an improvement journey and get some quick wins or wait until a thorough reliability strategy is in place to reduce the need for root cause analysis”… In other words, is it better to let the equipment fail and learn from that or put more effort into preventing the failures in the first place?

Lean is about people and processes through visual and effective manufacturing techniques. Combine this with much more detailed logical analysis process of reliability centred maintenance associated with the aircraft industry and you get a powerful tool: Lean RCM.

A Lean RCM approach develops a proactive strategy to ensure that your operational site or equipment runs reliably, in terms of asset performance, safety and quality AND at the same time reduces operating costs through the elimination of non-value adding activities. This process makes the best use of available resources to perform the reliability strategy. Remember you cannot be lean unless you’re reliable!

So what happens when a Lean RCM strategy has already been implemented? This is when an Operational Review and Root Cause Analysis strategy becomes crucial. It monitors the effectiveness of the reliability strategy and provides autonomous and empowered operational teams the means to continuously improve its effectiveness by analysing data and implementing logically derived improvement plans.

The other end of the scale, where a Lean RCM strategy has not yet been implemented, an Operational Review and Root Cause Analysis strategy helps to determine where on the plant the Lean RCM strategy should be applied next based on factual data analysis.

Two fundamental concepts are paramount to the success of this strategy. Firstly, the TEAM. The concept of autonomous and empowered operational teams consisting of operators and plant maintainers supported by technical functions and first line management. These operational teams are empowered to take ownership of plant performance and make the correct decisions and actions to improve plant performance using a variety of best practice techniques. Secondly, VISUAL MANAGEMENT. The use of highly visual management techniques in the operational review process that become the centerpiece of plant performance communication, review meetings and decision-making.

This strategy runs in parallel with a High-Performing Team so that both the operational teams and the operational team management fully understand the concepts, culture and behaviours of effective, autonomous and empowered work teams. In particular, the teams and managers need to understand, buy into, and practice the following key behaviours:

- A supportive leadership structure

- Key change management principles

- Enabling and empowering behaviours

- Accepting ownership

- Coaching and listening skills

- Effective communication

- Co-operation; Developing good team habits

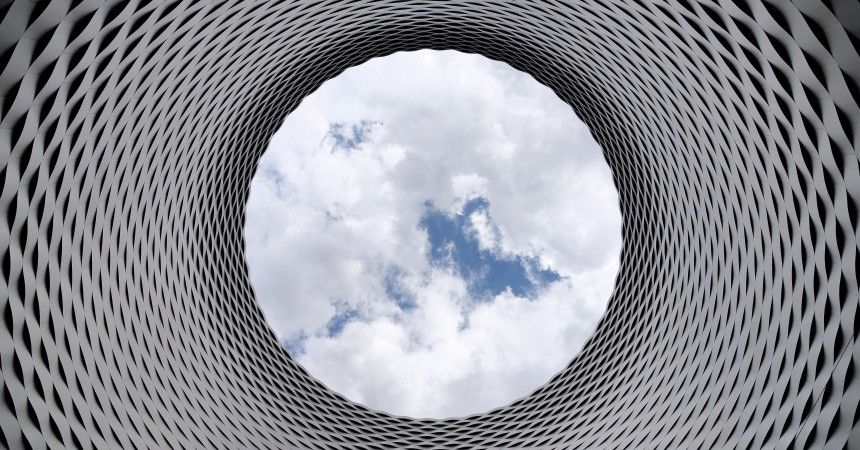

The answer; you cannot wait until you have completed the Lean RCM journey because, in truth, it never ends. The process of operational review and continuous improvement is like the compass of a ship telling you which way to steer the proactive efforts of your team to get the quickest wins. Often, quick wins underpin the sustainability of an improvement strategy. So start them both simultaneously and before you do try to imagine drilling the Channel Tunnel from both ends and when you meet in the middle you can see the light at the end of the tunnel.

Share: