Reading the Signs

This book caught my eye last month, whilst on my travels. It was in the famous City Lights Bookstore in San Francisco.

City Lights is an unusual place to find a book on a Lean tool, with it being a renowned independent bookstore-publisher that specialises in world literature, the arts, and progressive politics.

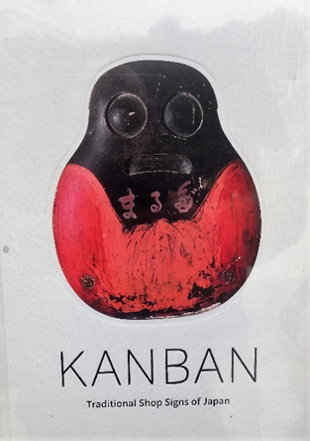

On further inspection, however, I found it was an art book on the traditional shop signs of Japan.

Kanban simply translates to sign or board.

Students of Lean thinking know that the term Kanban is used as part of the Toyota Production System which Toyota introduced in the late 1940s after studying supermarkets with the idea of applying shop supply chain techniques to the factory floor because the customer generally takes only what they need and the supermarket only replenishes to the level of customer demand to reduce wastage and therefore improve profits.

Applying Kanban to a manufacturing process ensured that stock levels aligned with actual consumption and by using a sign or signal enabled the supplier to produce and deliver more stock only when material is consumed.

This had the great advantage of:

- reducing waste and scrap material

- reducing inventory levels and overhead costs

- reducing overproduction

- minimising wait times

- streamlining production

- reducing the risk of obsolescence

- identifying and reacting to production issues quicker

I always find it fascinating finding new insights tracing back the history of Lean, learning more about the collection of proven management principles and ideas collated together to form a common sense system.

Also as a Lean practitioner for (ahem) a number of years now, it is satisfying to know that you can still always find out more on the history of continuous improvement and its many facets.

It is quite literally a physical and cerebral journey.

Reading the Signs

Share: