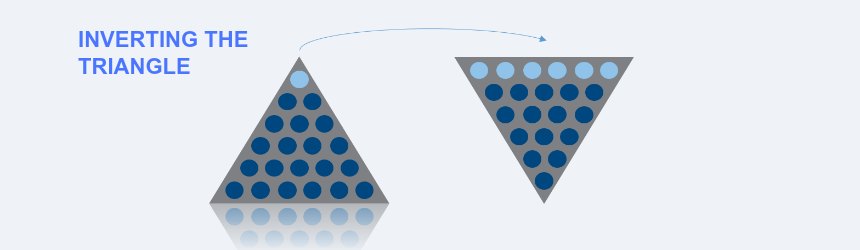

Tackling Resistance to Change – The benefit of ‘Inverted Triangle Thinking’

Ask any manager or team member in an organisation to draw out the organisational structure within their business and they will, as sure as fate, draw a triangle with the narrow part at the top of the page and the broad part of the triangle at the bottom of the page. Almost certainly, at the top of the triangle they will place the managing director or business leader and down at the bottom of the triangle they will show the workers and operators; those who do the work, use the equipment to manufacture the products that the customers buy. Talking of customers, when this person has drawn the organisation triangle they will almost certainly have missed off the customers from the organisation. Few people see, or fail to realise, that their customers are actually part of the organisation.

Everyone in an organisation is free to take on the responsibility of delivering the job to a high standard and to improving how effectively the job is done. The people doing each job within the business know best what is required to do the job better and, the managers know best how to provide these requirements.

Haven’t all companies already adapted to inverted triangle thinking? No, certainly not. Many companies believe they have inverted the triangle but they do not practice what they preach in that managers still make the decisions whilst workers simply yield tools.

How do I know if my company has inverted triangle culture?

Here’s 5 things to look for that may indicate how far along the journey of change your organisation actually is.

- Who runs the operational morning meeting? Is it the manager of the area or is it the operators within the area with the manager standing in the background present only to listen and to support if required

- Are there car parking spaces for Director’s right outside of the main entrance while workers have to park a long way from the factory entrance thus suffering the inconvenience of the UK weather as they walk past the directors shiny new vehicles?

- Do ideas come from manager’s meetings and get passed down to operational teams or do the operational teams have the time and freedom to get together to decide what they require and take these requirements to the managers for their agreement?

- Can the equipment operator explain to you how the production efficiency measure is calculated from first principles or does he tell you that he doesn’t understand it, it comes from a manager and is posted on the wall each week?

- In your manufacturing operation, if an operator has an equipment problem, does this get escalated to the operations manager who speaks to the maintenance manager who speaks to the maintainer or does the operator go straight to the maintainer and get the problem fixed?