IMPACT Masterclass™: Our Vehicle to Improve Productivity

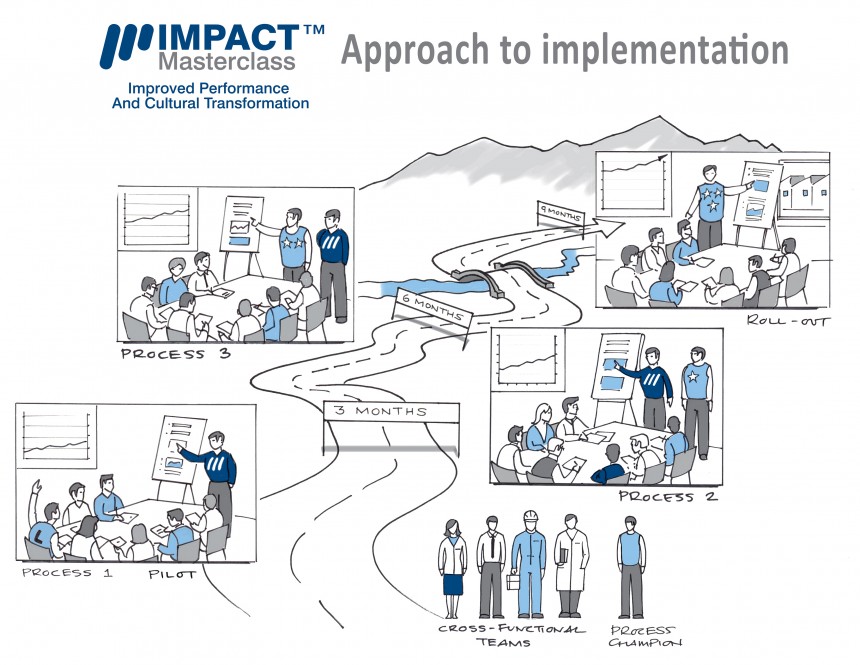

The IMPACT Masterclass™ is a 15-day Process Improvement Programme delivering a tangible improvement in productivity within just 3 months by combining and applying an optimised and bespoke set of Process Improvement tools and Change Management techniques specific to your business needs. By engaging and empowering cross-functional teams of people to make improvements directly within their day to day roles it creates belief, ownership and above all, sustainability.

IMPACT Masterclass™ Applications are:

IMPACT Masterclass™ Lean RCM – Process reliability improvement for asset-intensive businesses

IMPACT Masterclass™ Change–over Time Reduction – Reducing the time required to change between products increases capacity whilst reducing lead time & inventory

IMPACT Masterclass™ Process Improvement – Eliminating non-value adding activities maximises productivity increasing capacity and reducing cost

IMPACT Masterclass™ Process Improvement – Invisible-Processes – Improving business processes for Customer Service, Sales Finance, Administration, Marketing and all other business functions

IMPACT Masterclass™ Workplace Organisation – Building the foundations of productivity with an organised, efficient and safe working environment

There are 5 steps to the IMPACT Masterclass™:

Pre-diagnostic

Understanding the current state of the process to be improved, the operating environment and key performance figures. The cost-benefit analysis for the IMPACT Masterclass™ programme. Making preparations for the main part of the Masterclass.

Management Ownership Workshop

In Operational Excellence, it’s a well-known fact that management is responsible for all successes, and, all failures. Hence why it’s so important to ensure the site’s management team fully understand the programme elements and the end goal and therefore understand their role in providing the correct resources, support and active management throughout the programme and beyond. This is about challenging the management team to think differently; you cannot solve problems by using the same thinking that caused the problem in the first place.

Foundations Workshop

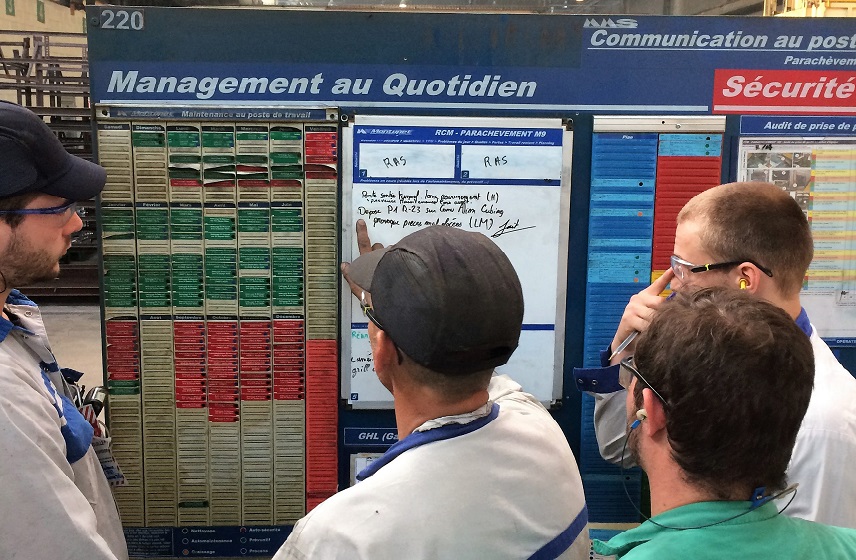

With the framework set and management committed to the end goal, it’s time for the multi-functional team to learn new process improvement skills and be guided through the application of these skills to their working environment to establish new ways of working delivering improvements and benefits.

Analysis & Implementation

Armed with a new set of skills and a desire for change and improvement, the multi-functional team systematically work through the process bottlenecks choosing an appropriate technique to solve problems at root cause level and determine the optimum solution for each. They shape and create their new way of working embedding and embracing the improvements as part of daily life.

Programme Review & Transferring Ownership to Internal Champions

Seeing is believing and when the IMPACT Masterclass™ team enthusiastically deliver their feedback presentation to the site management team the dialogue quickly turns to how do we make this our standard way of working across the whole site.

Sustainable business improvement requires ownership of problems and their resolution. By teaching others how to successfully facilitate the IMPACT Masterclass™, EMS Cognito encourages more rapid deployment of process improvement through self-sufficiency, in-house expertise and by creating ambassadors for change.