Process Reliability – transform an operation in to a world class maintenance standard

A reliable asset is available to perform the functions for which it was intended to the required standards of performance whenever it is required.

When reliable assets are combined it improves the consistency and repeatability of your processes leading to increased productivity, better safety, quality, customer service levels and the ability to extend equipment life cycles.

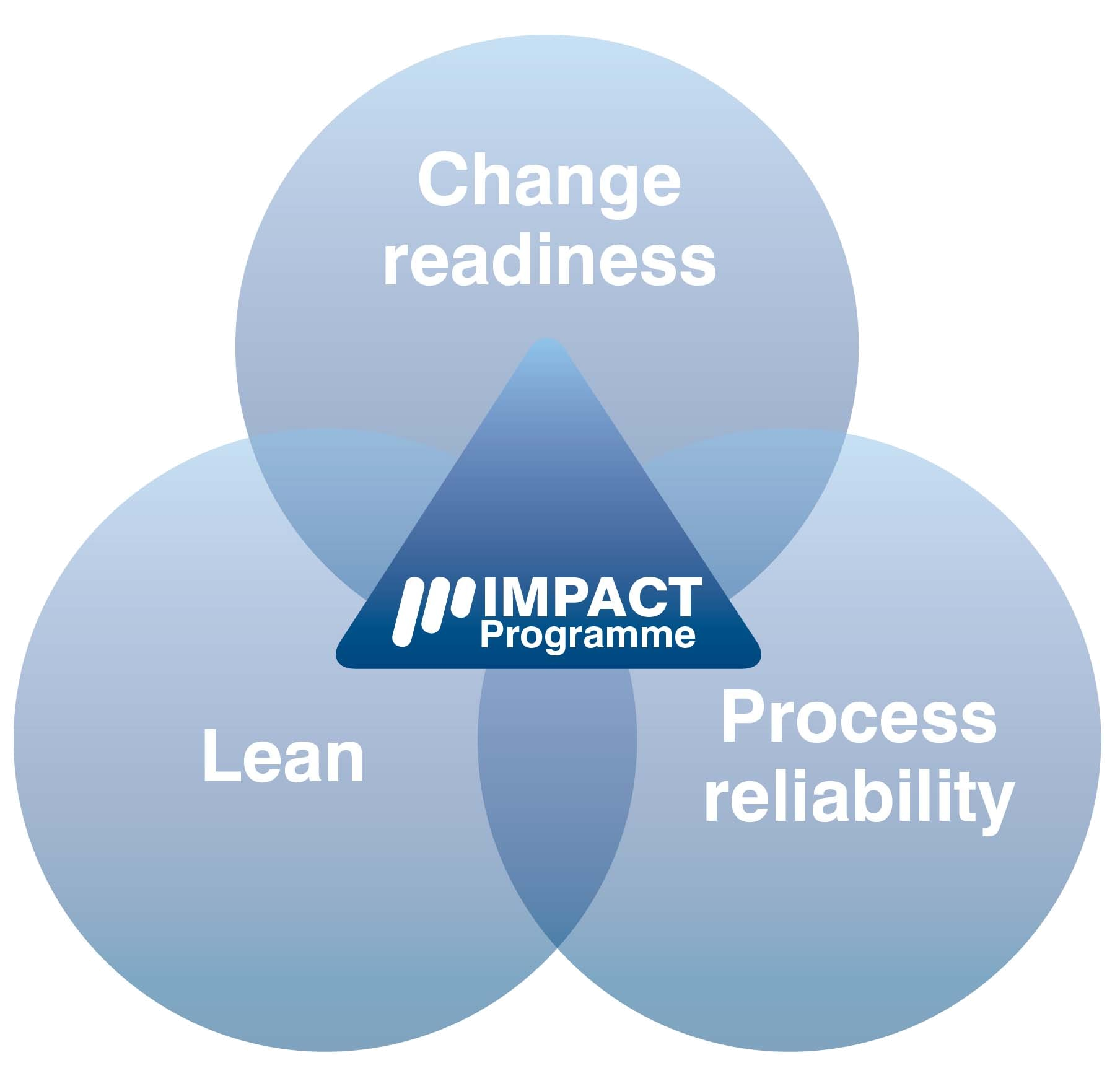

Our approach to process reliability is centred on Lean RCM™ a bespoke, tried and tested methodology for improving process reliability based on best practice within the aircraft industry – Reliability Centred Maintenance – blended with Lean Manufacturing, from industries such as the automotive sector, and our own, vast, proven experience within diverse industrial sectors.

IMPACT Masterclass™ Lean RCM™ programme is an award-winning, team-based, on-site programme delivering improvement in reliability in your environment in just three months

Our IMPACT Toolkit™ Workshops in Lean RCM™ and Root Cause Analysis provide you with the knowledge and skills to solve recurring problems and develop world-class preventive maintenance regimes

Out Maintenance and Reliability Audit is a 5-day, intensive on-site process to identify strengths and opportunities for improvement in your existing reliability strategy and provides you a road map for developing and implementing a world-class maintenance strategy; a journey on which we can support you some or all of the way.

Contact us today to find out how improving the reliability of your processes could make a difference to your business.

Email us at: info@emscognito.co.uk or call 0117 968 6595

Process Reliability in the Aircraft Industry

Process reliability is of central strategic importance to the aircraft industry. In 1978 a report written by two engineers at United Airlines became the blueprint for a revolution in the industry. Their research discovered that only 11% of breakdowns were due to the age of the equipment.

The technique that resulted from their work is referred to a Reliability Centred Maintenance (RCM) and it is now a World-class methodology employed by manufacturers globally who want to maximise asset reliability whilst reducing asset care costs.

Lean Management

In Japan in the early 1970s new lean management methods increased machine availability through better utilisation of maintenance and production resources. They facilitated autonomous maintenance by training the machine operators to perform many of the day-to-day tasks.

Lean RCM™

Reliability Centred Maintenance (RCM) and Lean are complementary philosophies that form a powerful combination. Lean helps to change the organisational culture and establish a process for continuous reliability improvement. RCM establishes a strong foundation for maintenance strategy. We have adapted these methodologies and integrated them into a system we call Lean RCM™.