Lean, Process Improvement and Reliability training for Practitioners, Managers & Continuous Improvement Facilitators

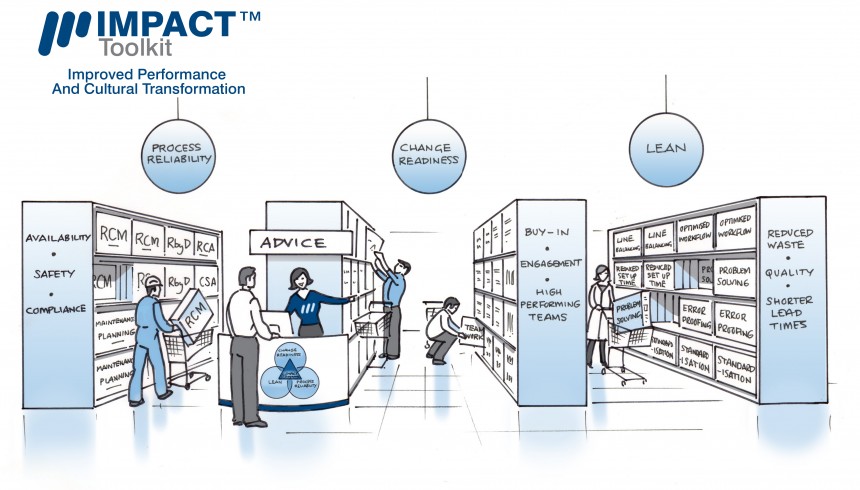

Our IMPACT Toolkit™ provides the knowledge, tools, techniques and templates to make sustainable productivity improvements in the workplace. An outline of each of our workshops is shown below with a link to a PDF containing full information about the workshop.

Check availability and dates for forthcoming IMPACT Toolkit™ workshops or contact us for more information.

Lean & Practical Process Improvement Fundamentals (Ref 401) (2 Days)

401 IMPACT Toolkit™ Lean and Process Improvement Fundamentals

A 2-day workshop for individuals or businesses new to Lean and Process Improvement and who want to understand more about its benefits, are seeking a template for efficient implementation, need tried & tested approaches to the barriers and concerns and who want an appreciation of how the techniques will be applied in their working environment.

Practical Process Improvement and Lean Tool Kit (Ref 402) (4 Days)

402 IMPACT Toolkit™ Practical Process Improvement and Lean Toolkit

A 4-day workshop for Continuous Improvement Practitioners and Facilitators incorporating process improvement techniques from PPI-5 (© Dr Mike Bell and R Edward Zunich 2015) with EMS Cognito IMPACT Programme™ Lean tools and techniques to debottleneck processes and improve productivity

5S for CI Facilitators (Ref 201) (2 Days)

201 IMPACT Toolkit™ 5S for Facilitators

Teaching you how to train others in 5S and facilitate successful, sustainable 5S programmes in your business. This is a highly practical workshop where delegates have the opportunity to practise 5S implementation during the workshop, test many of the theories and visualise the development of 5S in a safe learning environment.

Change-Over Time Reduction for Facilitators (Ref 501) (2 Days)

501 IMPACT Toolkit™ Change-Over-Time-Reduction for Facilitators

Teaching you how to train others in Change-over time reduction and facilitate successful, sustainable programmes in your business. This is a highly practical workshop where delegates will have the opportunity to practise Change-over time reduction techniques during the workshop in a safe learning environment

Root Cause Analysis (Ref 601) (2 Days)

601 IMPACT Toolkit™ Root Cause Analysis

This Workshop is a must-attend event for anyone working in Operations, Manufacturing, Maintenance, Production Engineering, Health and Safety, Quality, Customer service, Logistics and any other function of the business where finding the root cause of incidents or errors offers a fantastic learning opportunity for improvement

Introduction to Lean RCM™ (Ref 101) (3 Days)

101 IMPACT Toolkit™ Intro to Lean RCM™

Lean RCM™ is a bespoke, tried and tested methodology for improving process reliability based on best practice within the aircraft industry blended with Lean Manufacturing and our own, vast, proven experience within diverse industrial sectors.

This 3-day workshop gives you a complete understanding of the process and is guaranteed to provide a paradigm-shift in your approach towards reliability

Lean RCM™ Facilitation Skills (Ref 102) (4 Days)

102 IMPACT Toolkit™ Lean RCM™ Facilitation Skills

This on-site, workshop provides the competence to facilitate teams through a vast range of best practice improvement tools and techniques and is the next step in achieving the industry standard for Reliability Professionals; Lean RCM™ Facilitator

Lean RCM™ for Managers (Ref 103) (1 Day)

103 IMPACT Toolkit™ Lean RCM™ for Managers

This 1-day Workshop for Business Leaders, Maintenance, Engineering and Operations managers is to understand more about the theory of Lean RCM™, how to overcome the hurdles during implementation and how to transform an operation to a world class maintenance standard