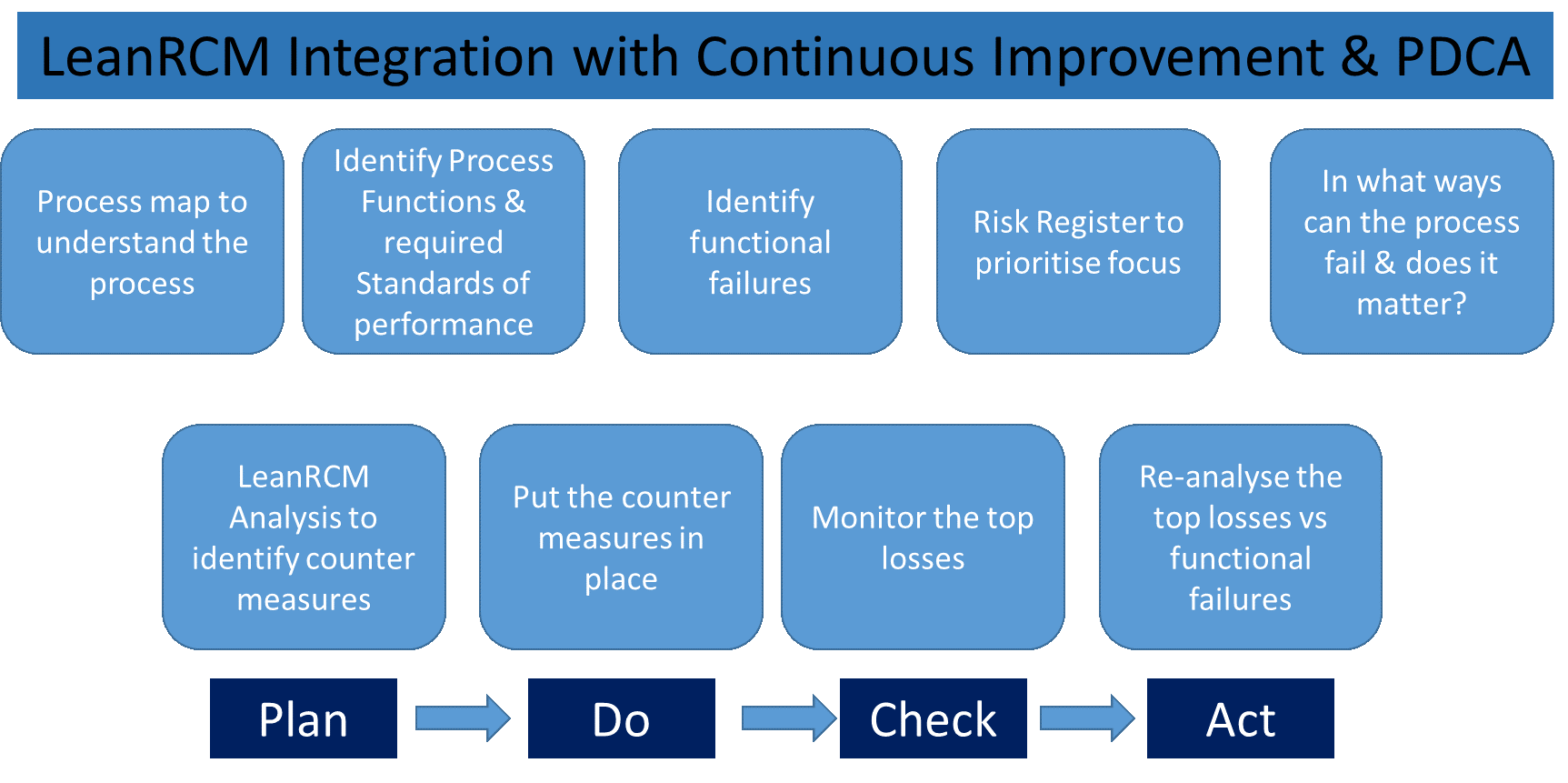

Lean RCM training can integrate with Continuous Improvement & PDCA

An IMPACT Masterclass™ Lean RCM programme will improve reliability. It is perfectly conceivable that 90% of the process failure modes will be identified during the Masterclass and appropriate control measures put in place to prevent them. So what about the other 10% and what if some of the assumptions on the 90% were slightly incorrect? The completion of the IMPACT Masterclass Lean RCM programme is not the end of the journey. The process needs to link to a continuous improvement process or integrate with an existing one. This integration requires training and awareness of those involved followed by adapting the way various are recorded. The continuous improvement process should, as most of them do, focus on the top losses over a given period i.e. a month. It should follow the normal plan-do-check-act format. What’s different about the Lean RCM training is that the top losses should link straight back into the Lean RCM analysis because:

- this already contains all of the known predicted failure modes for the process

- by referring back to this we can check if the assumptions were incorrect or

- are the control measures being implemented as planned or

- is this a new failure mode that was not anticipated and therefore needs to be added to the list

In order to do the above, we need to record plant failures against the appropriate functional failure they caused and not just the equipment name. These functional failures will already be listed in the Lean RCM analysis together with all the failure modes which could cause them. If, as in most cases, failures are just recorded against equipment name, this does not identify the key process which failed nor link back to the original analysis. Continuing to record failures against equipment name rather than functional failure after completion of the lean RCM analysis can lead to 3 scenarios; all the good work done in the analysis gradually becoming out of date, clutching at straws for root cause ideas or repeating the whole process again via some formal root cause analysis. In actual fact, the root cause analysis is already done it just needs to be added to. Guess what-Lean RCM analysis is a form of root cause analysis.

In order to do the above, we need to record plant failures against the appropriate functional failure they caused and not just the equipment name. These functional failures will already be listed in the Lean RCM analysis together with all the failure modes which could cause them. If, as in most cases, failures are just recorded against equipment name, this does not identify the key process which failed nor link back to the original analysis. Continuing to record failures against equipment name rather than functional failure after completion of the lean RCM analysis can lead to 3 scenarios; all the good work done in the analysis gradually becoming out of date, clutching at straws for root cause ideas or repeating the whole process again via some formal root cause analysis. In actual fact, the root cause analysis is already done it just needs to be added to. Guess what-Lean RCM analysis is a form of root cause analysis.

So how do we break this cycle?

Involve the continuous improvement team right from the start. They should be involved in identifying process functions, standards of performance and therefore understand the concept of Functional Failures. In this way, they will be more willing to adapt data recording systems to reflect functional failures rather than just a list of equipment. If you use a loss data capture database then the lean RCM approach dovetails very nicely. Rather than equipment names, populate the system with the functional failures from the Lean RCM analysis. Following a plant failure, the operator will choose the appropriate functional failure i.e. which process functional standard is not being achieved. Of course, to be able to do this, the concept of process mapping, process functions and standards and functional failures needs to be widely understood by the all operations team and central to continuous improvement.

Share: