The Power of Lean RCM – You Can’t be Lean if you Aren’t Reliable

I have just finished reading ‘Lead with Respect: A Novel of Lean Practice‘ by Michael Balle and Freddy Balle

In the book they talk about standards –

“…every team member is an essential worker no matter how complex the equipment they use…”

“…standards mean reference not rule they are there to be followed but most importantly to be improved…”

“There is nothing worse for an operator than to feel they’re doing their best, but that their boss is never happy with their work”

They go on to clarify:

-

Targets in terms of customer expectation

-

Step by step breakdown of the job

-

Necessary conditions to do the right work

-

Clear ‘OK’ vs ‘not OK’ judgement criteria

For me this is the perfect link to Lean RCM.

In the first instance during the pre-diagostic we work to understand what reliability means, in these terms the customer is often not thought of but it is critical to have a reliable plant if you want to meet your customer requirements, do you know what they are?

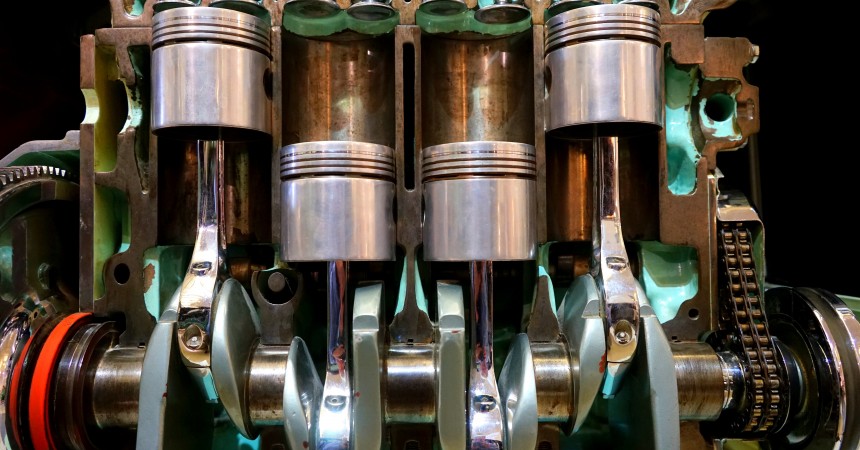

We then set out to understand what functions the equipment must perform, how these functions may fail and what tasks can be put in place to maintain that function thus giving a breakdown of the job. The individual knows why a task is important and a procedure details what they need to do, thus setting the standard.

The Standard operating procedure is key to training and implementing the reliability programme, a collection of documents written by the people who currently run the process detailing the current best way of performing that task. With labels to then support the standard that the team set for their plant.

This is often where people stop, fantastic SOPs that sit in the process and over time are not used directly. The problem then is you start to go back to the old habits. Remember before Lean RCM you had a preventative regime that was not followed, the key to making Lean RCM a success is to ensure it is always current and constantly improved. At a recent event a Lean RCM practitioner said at first they were annoyed when the same SOPs were coming back for alteration but over time he realised it was a good sign, the team were still using the SOPs to do the work, brilliant. I think we can take this two steps further.

At the conclusion of applying Lean RCM to a site generate a team training matrix listing the team across the top and all the SOPs down the side then tick who can do what task, people have different skills and some of the tasks may be electrically biased you will then have a clear visual who is trained to do what and the skills gap you have in your team. This also starts to break down the divide of ops and maintenance, it is a person’s skills that dictates what they can do not the function they currently reside in.

The next proposal I have is for the team leader or manager of the area to take back ownership and this reflects point 4, above. Constant feedback and confirming the standard to the team is the manager’s job. My proposal is taken from the book above but I think it is an excellent idea, every manager to spend 20 mins every day with one of their team, a different person everyday (not very long) and this is a coaching exercise. Take an SOP go with your team member and perform the task this way you are reviewing the task, setting the OK criteria and maybe even seeing a way to improve the task that is being done that can then be fed back through the analysis.

It’s not an easy task but think of the benefits and the relationships that will be built.

Share: